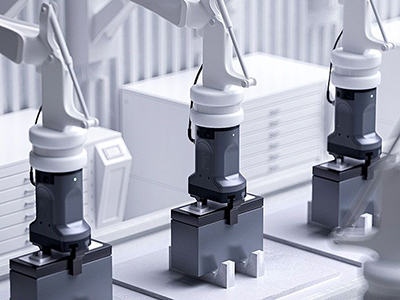

Lisebelisoa tsa indasteri

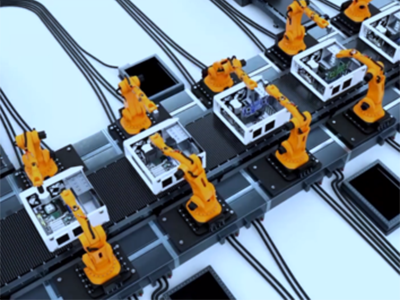

Indasteri ea tlhahiso ea lefats'e e ntse e kena butle-butle mehleng ea bohlale ba maemo a holimo.Ho na le tlhokahalo e ntseng e eketseha ea li-automation, informationatization, bohlale le poloko ea matla.Ka lebaka la nts'etsopele e tsoelang pele ea indasteri, ts'ebetso e nepahetseng ea theko e tlase le kopano e bohlale e fetohile sepheo sa mantlha sa nts'etsopele ea tlhahiso e bohlale liindastering tse fapaneng.

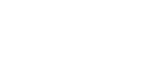

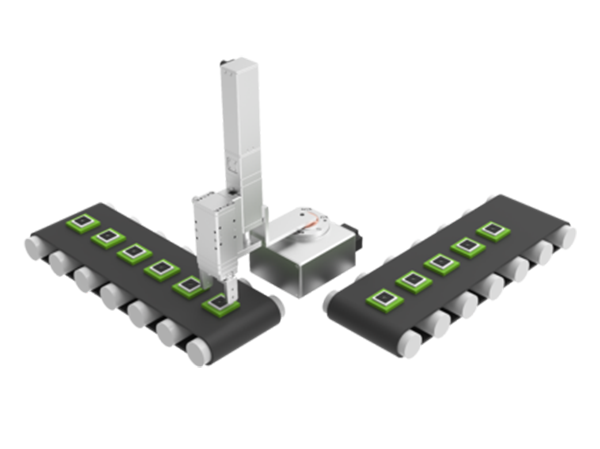

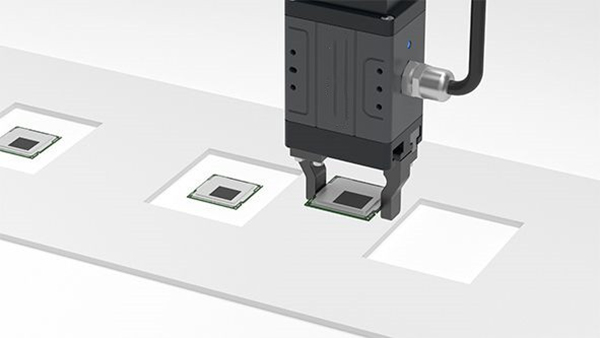

IC patch Tokiso ea boemo

Nakong ea ts'ebetso ea ho khetha le sebaka, ts'ebetso ea ho beha IC e etsoa ho lokisa boemo ba likarolo.Sebelisa li-gripper tse peli tsa motlakase ho lokisa boemo ka tsela e otlolohileng le e otlolohileng ka ho latellana.

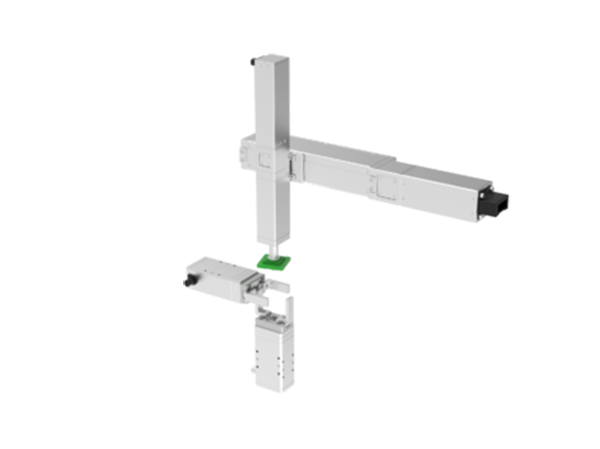

Tokiso ea boemo ba SMT

Tokiso ea boemo ba likarolo e etsoa ka ts'ebetso ea SMT.Sebelisa lithupa tse peli tsa motlakase ho lokisa boemo ka litsela tse fapaneng

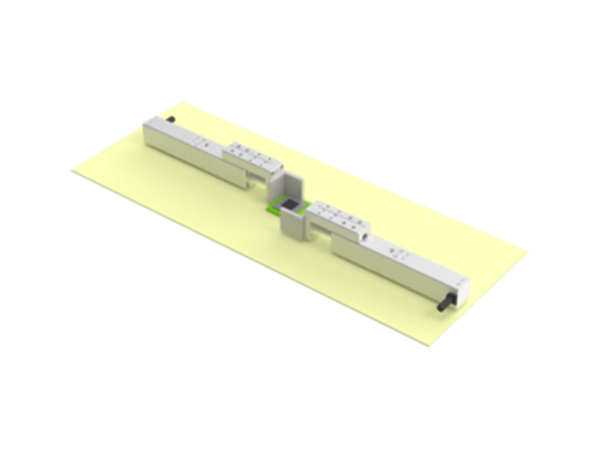

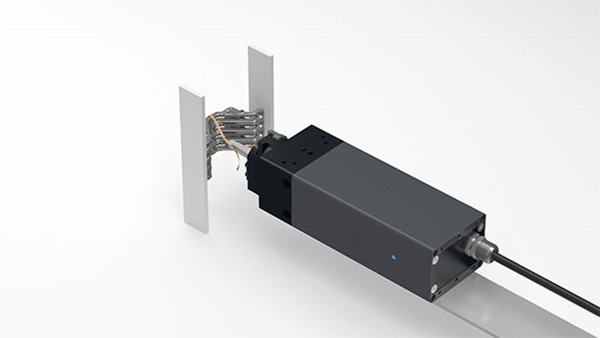

Ho fana le ho Welding

U sebelisa silinda ea motlakase ea CZ, tlhophiso e ka phethoa habonolo feela ka ho kenya boleng ba lebelo, lebelo le sisinyehang le lula le le teng, 'me ho tlotsa le ho cheselletsa ho lekana.

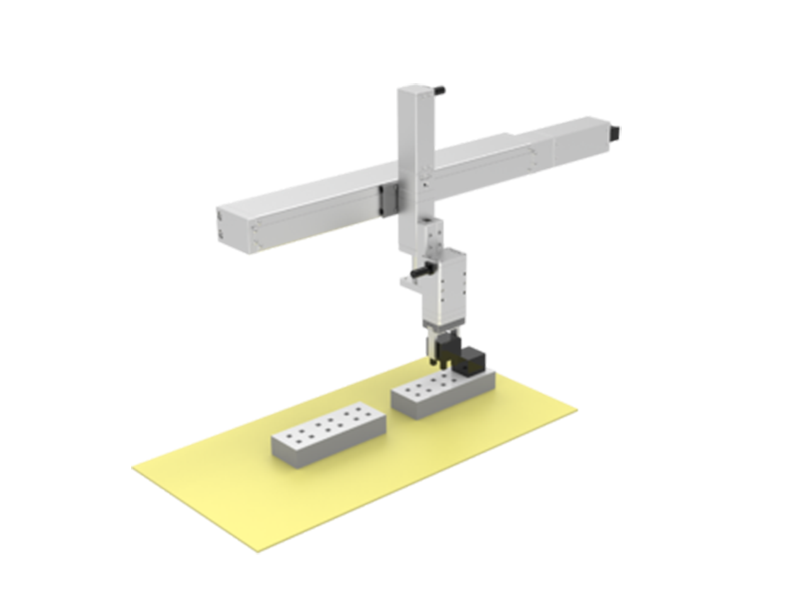

Tekanyo le Tlhophiso ea Mosebetsi

Sehlopha sa mamello se ipapisitse le litekanyo tsa mosebetsi tse lekantsoeng ka mehlahare ea gripper le ho hlophisoa ha li-workpiece ke li-actuator tsa CZ.

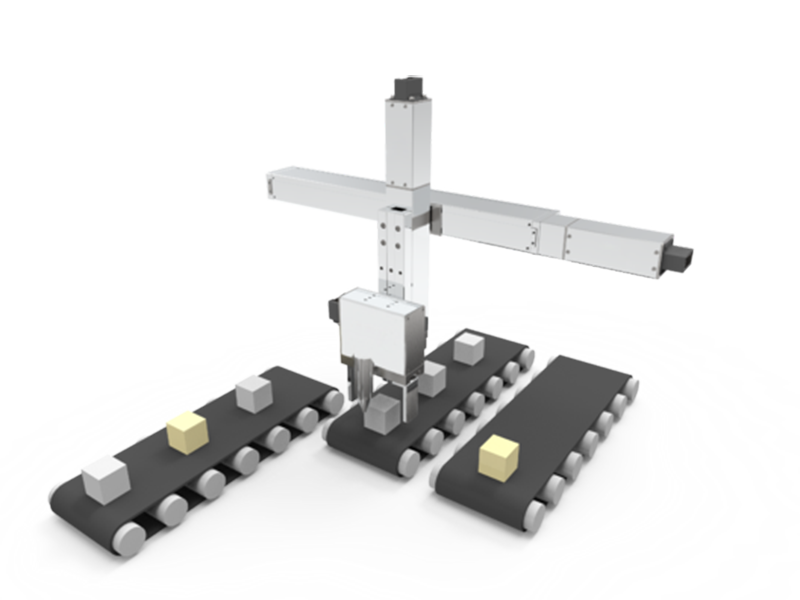

Phetiso ea rotary ea li-workpieces

Lokisa molamu oa motlakase holim'a tafole ea rotary, 'me u tsamaise sesebedisoa se holim'a lebanta la conveyor pele le morao ka motsamao oa rotary.

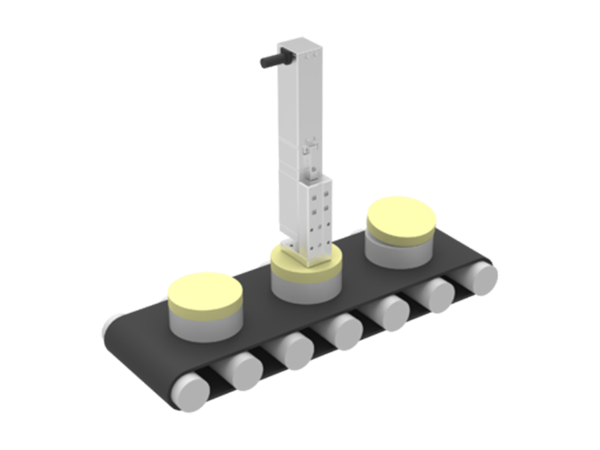

Phetiso ea mosebetsi

Tobetsa ka har'a sesebedisoa ka ho phahamisa ka motsamao o felletseng wa ho beha le ho theola ka ho sututsa.Ka ts'ebetso ea kahlolo, e fumanoa hore na ho na le phoso ho hatella sehlahisoa se nang le phoso kapa chuck ea workpiece.E sebelisoa ho "terminal press-fitting" ea likarolo tse nyane, riveting of housings, joalo-joalo.

Ho koala le ho riveting ea meriana ka ho sebelisa lithupa tsa push.

Ka ts'ebetso ea kahlolo, e fumanoa hore na ho na le mosebetsi o tsoileng matsoho kapa phoso e sieo ea sekoahelo

Liindasteri tse tummeng

Boiketsetso ba bongaka

Tsa elektroniki

Tsa makoloi

Boiketsetso

Sesebelisoa sa lapeng

Lenane la likopo

3C lisebelisoa tsa elektroniki

Likarolo tsa Auto

Life Sciences

Matla a macha le betri ea lithium

Semiconductor

Matla a Macha

Lisebelisoa tsa Smart

Maemo a Kopo

Likarolo tsa Auto ho hlobolisa thapo ea motlakase

Ho sebetsana le chip

Ho hlopha liphutheloana tsa thepa

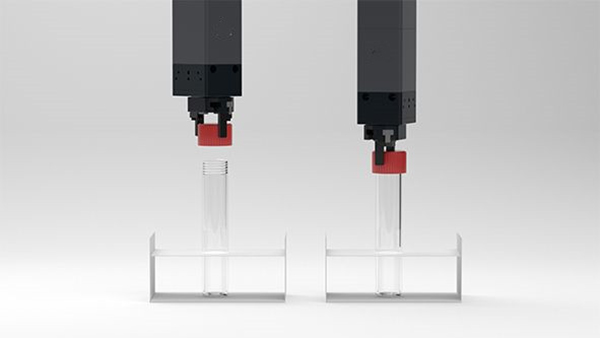

Ho bula le ho Koalloa ha Likotlolo tsa Lithethefatsi

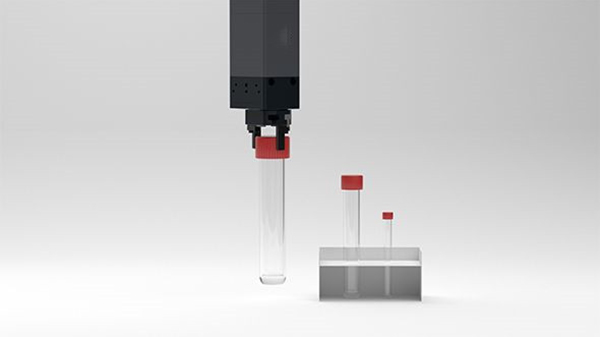

Ho bula le ho koala sekwahelo sa tube ea teko

Packaging Auto Parts

Ho khetha li-tubes tsa liteko tsa mefuta e mengata

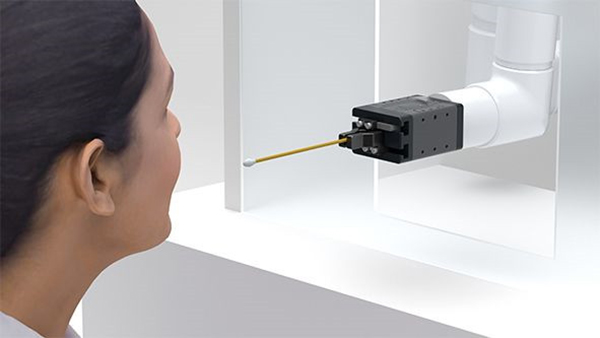

Ho sibolloa ha nucleic acid e se nang motho